News

Cotton Fabric Pre-treatment Processes for Better Dyeing/Printing Effects

The most attractive features of a garment are its appearance including colour, texture, shine and feel. Retailers look for developing smooth and comfortable garments that the customers will most likely purchase. But to achieve such effects, the mill made fabrics need to undergo several pre-treatment processes before they are dyed or printed.

Pre-treatment processes help eliminate added and natural impurities from the fabrics like natural colour of the fibres, sizing materials, oils, waxes, starch, spots, seed particles, soils and other impurities which affect the fabric’s absorbency, appearance, fullness of shade development, dye affinity and handle. During weaving of cotton yarns into fabrics, the yarns are given a sizing treatment to develop strength to bear the tension during weaving. The sizing paste consists of starch, oils and lubricating materials which hinders the absorbency of the fabric. The fabric develops several defects during weaving like spots and oil marks. These external matter present on the fabrics needs to be removed so that the fabric can be further dyed/printed or finished with best effects (Sisodia & Parmar, 2019).

Purpose of fabric pre-treatments

To remove all impurities and immature fibres present in the fabric

• To improve uniform dye uptake capacity

• To improve moisture absorbency and hydrophilicity

• To achieve required degree of whiteness for exact shade development

• To improve fabric softness and handle, lustre, feel and texture.

The fabric pre-treatment process includes several dry-processing and wet processing stages like grey cloth inspection, shearing and cropping, singeing, desizing, scouring, bleaching, souring, washing, mercerising, and dyeing/printing.

a). Grey cloth inspection – The fabric obtained from the weaving department is called grey/greige cloth. It is inspected for visible defects, loose or floating threads, spots and oil marks, determining fibre type/blend type, etc. Then fabrics are stitched together with synthetic yarns (polyester cotton blend 80:20 ratio) on sewing machines to create continuous lengths of fabrics for further processes.

b). Shearing and cropping – This is done to remove any long protruding threads or loose threads lying on the surface of the fabric. During this process a metal detector is also fixed with the cropping or shearing machine so that it can detect any presence of metal particles in the fabric that can be removed manually.

c) Singeing – It is a mechanical process done to remove short, protruding fibres from the yarn interstices in the fabrics. These are very short and thin fibres that cannot be removed during the shearing process. These protruding fibres affect the dyeing/printing effect, smoothness and lustre of the fabric. They give a hazy appearance to the fabric known as frosting. Singeing improves the aesthetic values like smoothness, evenness, clean appearance and shine of the fabric. Clear and sharp printing effects could be achieved with singeing. The fabric passes through a singeing machine. The first region of the machine has brush rollers that brush out the short fibres protruding from the yarn interstices. Then the fabric enters a burning zone at high speed (50-300m/min) with two rows of flames, one facing the top surface and the other facing the bottom surface of the fabric. These flames burn out the protruding fibres. Finally, the fabric passes through a quench bath that extinguishes the sparks and cools the fabric. There are four types of singeing techniques namely Plate singeing, Roller singeing, Gas singeing and Enzyme singeing techniques.

d) Scouring – This process is also known as ‘kiering’, ‘kier boiling’, ‘boiling-out’ or ‘boiling’. The main purpose of scouring is to remove natural as well as added impurities like oils, fats, waxes, etc present in the cotton yarn/fabric and improve fabric absorbency. It makes the fabric highly absorbent without damaging it. Chemicals used are caustic soda (NaOH) sodium silicate (Na2SiO3) Soda ash (Na2CO3). After the process of scouring, the fabric is thoroughly washed to remove any traces of alkali in it.

Action of alkali during scouring

• Caustic soda helps in saponification of oils (oils are converted to soaps).

• Hydrolysis of fats and waxes.

• Break down pectins and proteins to soluble pectates.

• Swelling of cellulose to facilitate easier and quicker penetration of liquor.

• Mineral matters are dissolved.

• Other oils matter that cannot be converted to soap are emulsified.

• Dirt particles are removed and held in suspension.

e) Desizing – Desizing helps in the removal of size material or starch from the yarn/fabric by the process of hydrolysis of starch. The size material consists of starch, binder, softener, lubricants etc. Starch is an insoluble matter. During hydrolysis, starch (insoluble) gets converted to dextrin (insoluble) which further changes into soluble dextrin. It is further broken down to maltose (soluble) and then finally converted to the soluble alpha-glucose molecules. This can be removed by washing thoroughly with clean water. Desizing can be carried out in hydrolytic method by using water (rot steeping), acid (diluted HCl), enzyme (bacterial amylases) or oxidative methods using alkalis and chemicals followed by washing and rinsing.

f) Bleaching – Bleaching is done to remove the natural colouring matter present in the cloth or yarn in order to obtain high degree of whiteness and uniform appearance of the fabric. Bleached fabrics can be dyed to obtain bright shades, improved brilliance, and exact shades of the dyes. This process is also known as ‘chemicking’. Bleaching can be carried out using different bleaching agents followed by hot water washing, rinsing and neutralisation as explained below:

• Calcium Hypochlorite [Ca(OCl)2] bleaching (use of bleaching powder)

The scoured fabric is treated in a hypochlorite solution at room temperature. Nascent chlorine is liberated. This decomposes the matter into HCl and nascent oxygen [O]. This nascent oxygen is responsible for the bleaching action.

• Sodium Hypochlorite (NaOCl) bleaching

This is expensive than calcium hypochlorite bleach. It can give more thorough bleaching action as the sodium ions are smaller in size than calcium ions. Therefore, it has higher ability for diffusion and shorter time of bleaching.

• Hydrogen Peroxide (H2O2) bleaching

Hydrogen Peroxide is known as the universal bleaching agent and extensively used. It can be used for cotton, silk, wool and jute. The peroxide bleach requires less water, produces better absorbent goods, better whiteness and is a safer process. Continuous scouring and bleaching is possible in one operation. Souring process is not required after bleaching.

• Sodium Chlorite (NaClO2) bleaching

It is a safe bleaching process and does not damage the fabric. Good white effects can be obtained in the fabric.

g) Souring – This process is done after bleaching. Souring is done to neutralise the alkali present in the fabric during the process of bleaching. Therefore, dilute mineral acids like dilute hydrochloric acid or dilute sulphuric acid (1-20 Tw) or acetic acid (CH3COOH) is used at room temperatures. The fabric is then thoroughly washed with water to remove any residues and then dried. Any such residue will affect the fabric strength, texture, feel and quality in the long run. Hence, it must be thoroughly washed before being used for any further processes.

h) Mercerising – Mercerisation is a chemical treatment of cotton material with concentrated caustic soda (NaOH) under tension to impart a permanent lustre and smoothness in the fabric. The process consists of treating cotton yarn or cloth in concentrated caustic soda (50-550 Tw) for a few minutes under tension. A considerable shrinkage upto 25 per cent of the length of the material is achieved. The strength of the material is increased by 40 per cent. The process is followed by washing, then souring, washing and drying. (Harane & Adivarekar, 2016).

Action of mercerisation

When cotton material is dipped in a caustic soda solution, the fibre swells up and becomes rounder in shape. This happens due to the removal of convolutions from the fibre. The alkali is absorbed not only into the amorphous regions of the cellulose but also penetrates into the crystalline region. So, a lateral swelling of fibre occurs, and the convoluted shape of the fibre becomes circular. As a result of which the fibres become absorbent and dye uptake capacity of the material increases. This also results in shrinkage of yarn because as the fibre swells laterally within the spiral yarn structure, the whole yarn expands in diameter and the fibres form greater angles and traverse greater distances around the spiral, thus decreasing the length of the yarn causing shrinkage.

Benefits of mercerisation on a cotton fabric:

• It imparts lustre to the fabric

• Increases the dye uptake capacity and helps in uniform dyeing effect

• Increases the tensile strength

• Reduces the value of coefficient of friction thus fabric surface roughness is lowered

• Gives a translucent finish to cotton goods like lawns, voiles etc

• It also results in shrinkage of the fabric due to swelling of the yarn

• Reduces the bending length, rigidity/stiffness

• Improves fabric softness and handle

• Improves crease recovery properties.

Therefore, proper chemical and mechanical pre-treatments of the cotton material help to optimise the dye and print quality. The dyeing or print quality on pre-treated cotton fabrics is not affected by the fabric structure and hydrophilicity of the fabric surfaces because the pre-treatments give the cotton fabrics a balanced hydrophilic/hydrophobic character. Pre-treatments also help in developing higher colour absorption capacity, good colour retention property and line width control of the fabric.

News

What’s Involved in the Personal Injury Claim Process

If you have sustained injuries because of another person’s negligence can file a personal injury claim to seek damages. However, it can feel complicated if it is your first time going through the claim process. Because of this, you can make mistakes. Sadly, even a simple mistake in this type of case can decrease your odds of securing compensation for your injuries. To avoid these mistakes, you should seek legal advice from an experienced personal injury attorney.

It’s not a legal requirement to hire an attorney to file an injury claim. However, hiring an attorney is usually the first step. The right lawyer can help you throughout each step of the process, which includes ensuring you have the right to sue. Below are the steps involved in the personal injury claim process:

Screening

As the injured party who wants to initiate a lawsuit, you must contact a lawyer for a consultation first. This allows you to talk about your case and the injuries you have suffered. During this consultation, the attorney may ask you to sign a document that authorizes them to access your medical records. The lawyer will ask about your insurance coverage, whether an insurance adjuster has contacted you, and what transpired during your conversation with them.

Once the lawyer accepts the case, they will thoroughly investigate the accident. This includes speaking with witnesses, collecting and preserving evidence, and contacting insurance companies.

Settlement Negotiations

Before you file a lawsuit, your lawyer will contact the insurance company of the at-fault party to determine if they can reach a fair settlement of your case before you to go court. Based on the circumstances and facts of your case, your lawyer drafts a demand letter with a settlement amount and send this to the insurance company. If both parties cannot reach an agreement, litigation can ensue.

Complaint Filing and Serving

Your lawyer will file the complaint with the court, triggering the litigation process. Then, the defendant will get a summons that notify them of your complaint and the amount of time they have to respond to it.

Discovery

During the discovery process, lawyers for both sides gather details and testimony, documents, and evidence related to the case. Discovery comes in the form of written discovery, depositions, and production of documents.

The discovery process is then followed by hiring expert witnesses, filing pre-trial motions, and going through mediation. These steps are meant to try to help both parties settle their case before going to trial. However, if they fail to resolve their issues during these steps trial will occur in court.

News

Hh gregg A Tale of Retail Resilience and Transformation

In the world of retail, few names are as iconic as hh gregg. This article delves into the fascinating journey of this retail giant, from its inception to its rebranding as Gregg’s, and the impact it left on the retail market.

| Heading | Subheading |

|---|---|

| Introduction | |

| The Rise and Fall | |

| Rebranding as Gregg’s | |

| Products and Services | |

| Customer Experience | |

| Online Presence | |

| Impact on Retail Market | |

| Conclusion |

Introduction

Once a household name in the electronics and appliances retail industry, hh gregg was known for its wide range of products and exceptional customer service. However, its story is not just one of success but also resilience and transformation.

The Rise and Fall

hh gregg’s rise to prominence was meteoric. Established in 1955 by Henry Harold Gregg and his wife, Fansy, as an appliance and electronics store in Indianapolis, Indiana, the company quickly expanded its footprint across the United States. With its commitment to delivering quality products and personalized service, hh gregg became a go-to destination for consumers seeking appliances, electronics, and more.

The fall of hh gregg, on the other hand, was equally dramatic. In 2017, the company filed for bankruptcy and subsequently closed all its stores. The reasons behind this decline were complex, including increased competition and changing consumer preferences.

Rebranding as Gregg’s

Despite the setback, the hh gregg story didn’t end there. The company underwent a remarkable transformation and rebranded itself as Gregg’s. This rebranding effort aimed to leverage the brand’s legacy while adapting to the changing retail landscape.

Products and Services

Gregg’s continued to offer a wide array of products, including appliances, electronics, and furniture. However, it also diversified into new categories such as smart home technology, emphasizing innovation and staying up-to-date with consumer demands.

Customer Experience

One thing that remained unchanged was Gregg’s commitment to customer experience. The brand focused on delivering exceptional service, ensuring that customers felt valued and supported in their purchasing decisions.

Online Presence

In the digital age, Gregg’s recognized the importance of an online presence. They invested in user-friendly websites and mobile apps, making it convenient for customers to browse, purchase, and track their orders from the comfort of their homes.

Impact on Retail Market

Gregg’s reentry into the retail scene had a significant impact. The company’s success story served as a beacon of hope for the retail industry, showcasing that reinvention and adaptation could breathe new life into even the most established brands.

Conclusion

In conclusion, the transformation of hh gregg into Gregg’s is a testament to the resilience and adaptability of retail brands. It demonstrates the importance of understanding customer needs and embracing change to thrive in an ever-evolving market.

FAQs

1. What led to hh gregg’s decline and bankruptcy?

The decline of hh gregg was influenced by factors like increased competition, changing consumer preferences, and financial challenges.

2. How did Gregg’s rebrand itself successfully?

Gregg’s successfully rebranded by diversifying its product offerings, focusing on customer experience, and establishing a robust online presence.

3. What products can I find at Gregg’s today?

Gregg’s offers a wide range of products, including appliances, electronics, furniture, and smart home technology.

4. How can I access Gregg’s online services?

You can easily access Gregg’s products and services through their user-friendly website and mobile app.

5. What can other retailers learn from Gregg’s transformation?

Other retailers can learn that adaptability and a customer-centric approach are key to surviving and thriving in the dynamic retail market.

News

Sonic Youth: The Revolutionary Band That Redefined Alternative Music

Sonic Youth was a groundbreaking band that emerged in the early 1980s and quickly became a significant influence on the alternative music scene. Combining elements of punk rock, noise, and experimental music, the band created a distinctive sound that challenged conventional ideas about music and paved the way for countless other artists to explore new sonic possibilities.

In this article, we will explore the history of Sonic Youth, their impact on the music world, and their enduring legacy. From their early days in New York City’s vibrant downtown scene to their final performance in 2011, we will examine the band’s journey and celebrate their contributions to alternative music.

Introduction to Sonic Youth

Sonic Youth formed in 1981 in New York City’s Greenwich Village, where they quickly established themselves as a force to be reckoned with in the underground music scene. The band consisted of Thurston Moore, Lee Ranaldo, Kim Gordon, and Steve Shelley, and their sound was characterized by dissonant guitars, unconventional song structures, and a willingness to experiment with noise and feedback.

Early Years and Rise to Fame

Sonic Youth’s early years were marked by a series of independent releases and collaborations with other artists. However, it was their 1988 album “Daydream Nation” that propelled them to international fame and critical acclaim. The album was hailed as a masterpiece and remains one of the most influential alternative albums of all time.

Sonic Youth’s Unique Sound

Sonic Youth’s sound was defined by their use of alternate guitar tunings, unorthodox playing techniques, and a willingness to experiment with noise and feedback. This approach was heavily influenced by avant-garde composers like John Cage and minimalists like La Monte Young. The band’s willingness to push the boundaries of what was considered acceptable in popular music helped to redefine the alternative music scene and paved the way for countless other artists to experiment with sound.

Sonic Youth’s Impact on Alternative Music

Sonic Youth’s impact on alternative music cannot be overstated. The band’s willingness to experiment with sound and push the boundaries of what was considered acceptable in popular music paved the way for countless other artists to explore new sonic possibilities. Bands like Nirvana, Pixies, and Sonic Youth’s own record label, SST Records, were all heavily influenced by the band’s unique sound and approach to music.

Sonic Youth’s Legacy

Sonic Youth’s legacy continues to live on in the music of countless other artists. The band’s willingness to experiment with sound and push the boundaries of what was considered acceptable in popular music helped to redefine the alternative music scene and paved the way for countless other artists to explore new sonic possibilities. Sonic Youth’s influence can be heard in the music of bands like My Bloody Valentine, Radiohead, and Arcade Fire, to name just a few.

Conclusion

Sonic Youth was a band that redefined what was possible in alternative music. Their unique sound, willingness to experiment with noise and feedback, and refusal to be bound by conventional song structures helped to pave the way for countless other artists to explore new sonic possibilities. Sonic Youth’s legacy continues to live on in the music of countless other artists, and their influence on alternative music will be felt for generations to come.

FAQs

- When did Sonic Youth form?

- Sonic Youth formed in 1981 in New York City’s Greenwich Village.

- Who were the members of Sonic Youth?

- The band consisted of Thurston Moore, Lee Ranaldo, Kim Gordon, and Steve Shelley.

- What was Sonic Youth’s unique sound?

- Sonic Youth’s sound was characterized by dissonant guitars, unconventional song structures, and a willingness to experiment with noise and feedback.

- What was Sonic Youth’s most influential album?

-

Entertainment1 year ago

Entertainment1 year agoAdmiral casino biz login

-

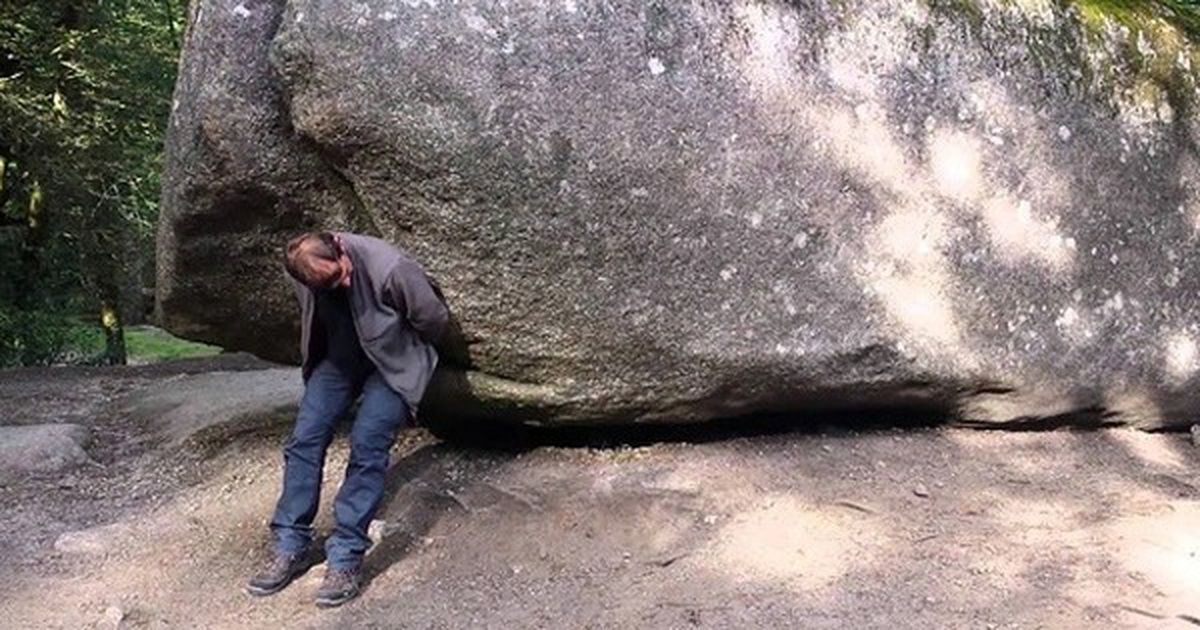

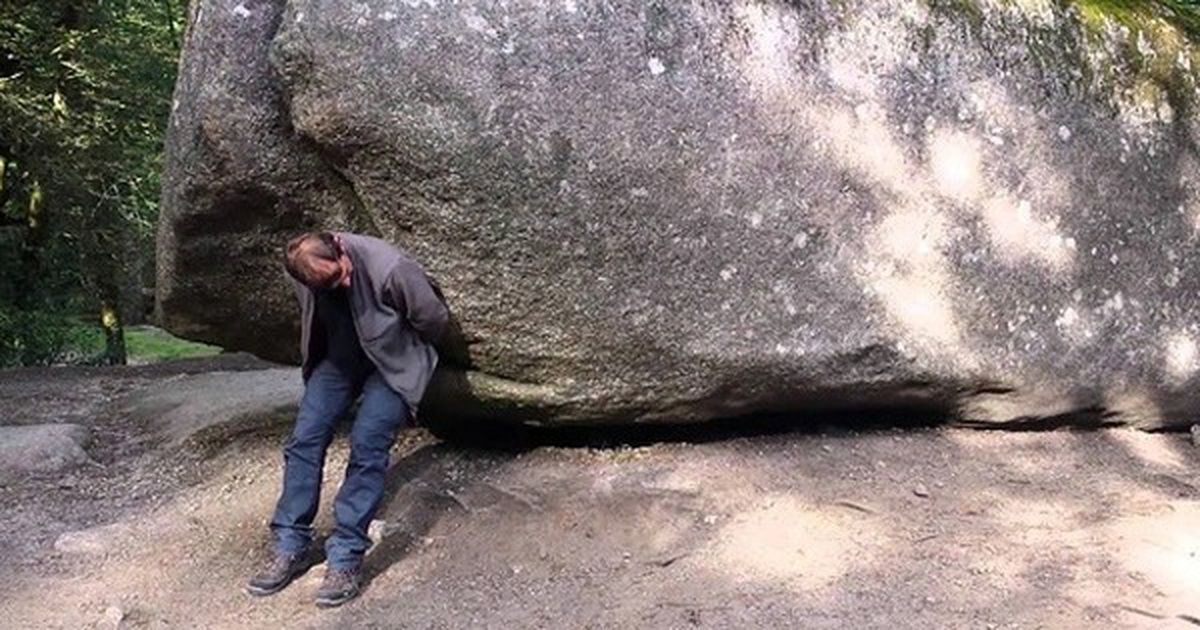

Entertainment2 years ago

Entertainment2 years agoHow Much Does The Rock Weigh

-

Entertainment2 years ago

Entertainment2 years agoDownload Popular Latest Mp3 Ringtones for android and IOS mobiles

-

Entertainment2 years ago

Entertainment2 years agoTop 10 Apps Like MediaBox HD for Android and iPhone

-

LIFESTYLE2 years ago

LIFESTYLE2 years agoWhose Heartland?: The politics of place in a rural–urban interface

-

Fashion3 years ago

Fashion3 years agoHow fashion rules the world

-

Fashion Youth2 years ago

Fashion Youth2 years agoHow To Choose the Perfect Necklace for Her

-

Fashion Today2 years ago

Fashion Today2 years agoDifferent Types Of lady purse